Hi John

Firstly you will always have reverse gear and 3rd. all the time the car is running in what they call

LIMP MODE and the car will continue to drive like this continually until the fault is sorted… I

have driven a gto in limp mode for over a year with finding only one added problem that isn’t

apparent until you try giving the car some gun so to speak… accelerate hard and the oil in the

gearbox will become much hotter and will start to cut the engine making it die… not to cleaver

when it happens as your in the middle of overtaking another car which is what happened to me

when I first experienced that limp mode has the ability of being able to cut the engine off

completely… if this happens then simply slow down until the oil has a chance to cool and the car

will run fine again… but now treat it with a bit of respect and shouldn’t happen again…

In limp mode you should also have lost Kick Down and also Overdrive…

There should be two main plugs coming from the wiring loom that connect to the gear box and

also a single Blue wire that connects to the front of the gearbox near the rad which is the high oil

temperature sensor lead.

The two main loom plugs are very different in size as one has only 4 wires going though it where

as the other contains a large number of wires… they both should first be check and connections

cleaned… BUT its the small 4 wire plug you need to be interested in as this connects the 4

electrical shift solenoids inside the box to the main wiring loom on the car…

Finding the two plugs is very simple… first remove the air filter box lid if your car is still using

the original air filter… 4 lever type of clips and disconnect one loom plug going to the box

should make it so you can lift to lid of the air cleaner box out of the way by bending the rubber

pipe going to it with that still attached to the engine.

The 4 pin plug should be roughly beneath it slightly toward the front of the car

The much larger plug can be in either of two places on the car…

1… connects directly next to where the gear selector lever enters the box

2… or has a small wiring loom coming from next to where the gear selector lever enters the box

and has it’s main plug next to the car battery.

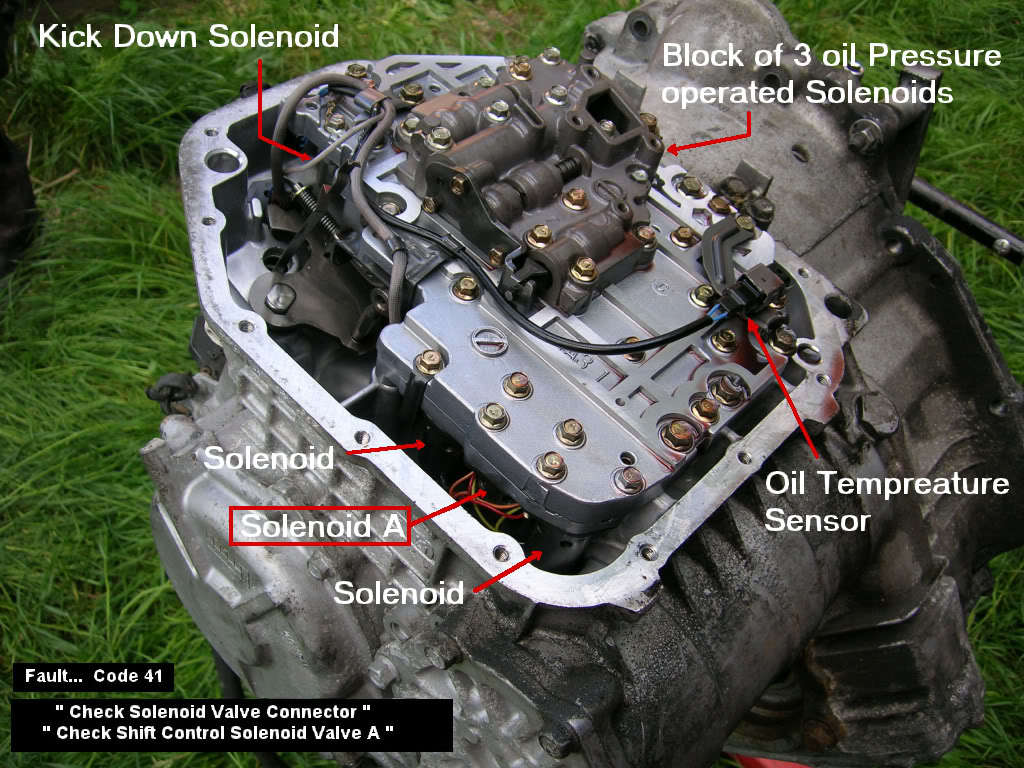

Inside the box are 4 electrical shift solenoids… a batch of 3 close to each other and one on its

own across the other side of the gearbox inside… the one on it’s own is the Kick down solenoid

and if remember correctly has a blue wire going to the 4 pin loom plug you need to check…

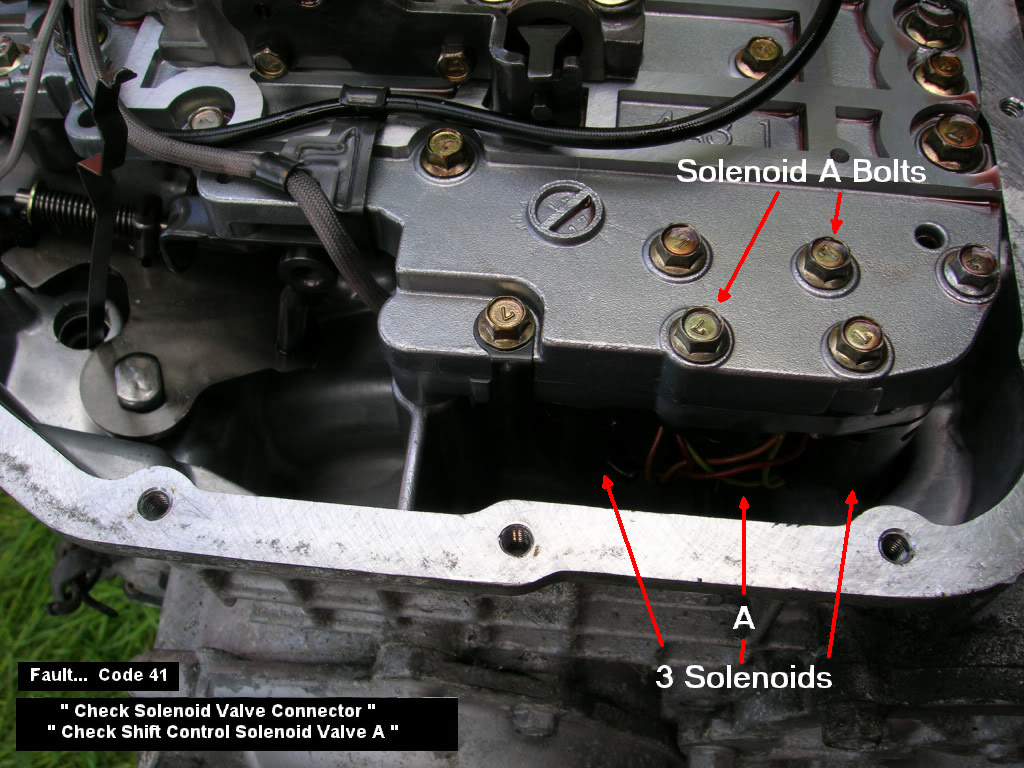

SHIFT CONTROL SOLENOID A is the middle one of the batch of 3 next to each other…

The 3 remaining wire going to the 4 pin plug should be ORANGE… RED… GREEN with the last

of the 4 being the BLUE that runs the Kick down

I can not be 100% sure which colour wire controls solenoid A without taking another look inside

a box I have thats not in a car and Don’t be fooled by looking at the pics I’ve placed below as

they don’t all go to the solenoid they look to be going to in the picture.

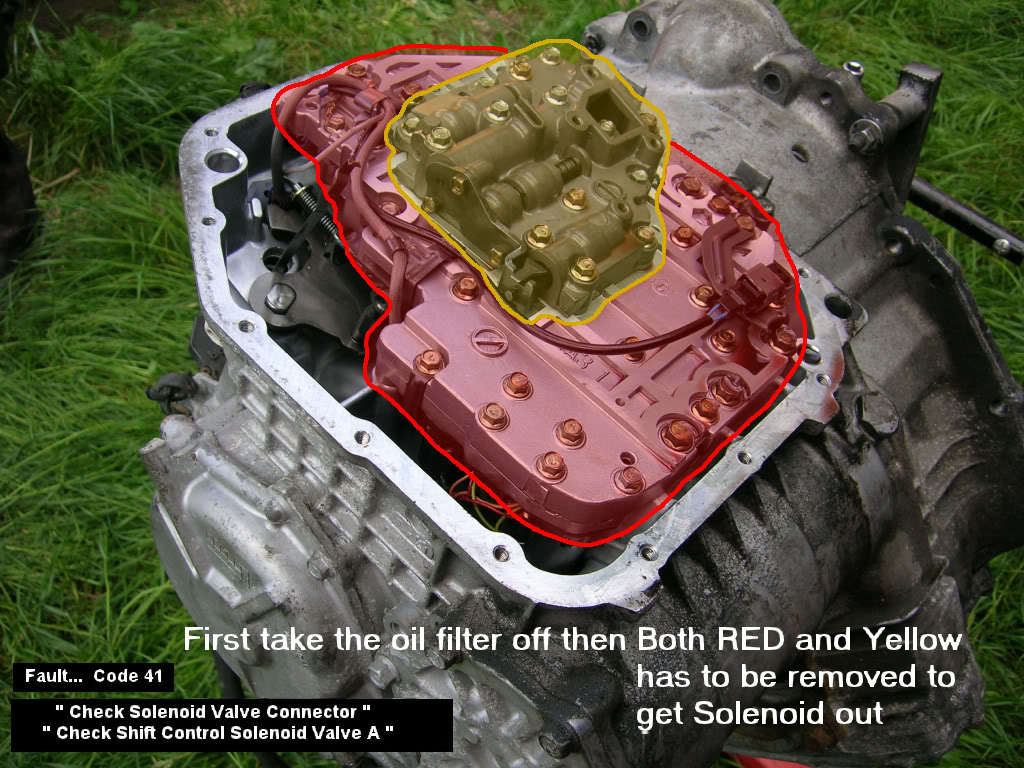

All these solenoids are replaceable but hope your not frightened by what you’ll see would need

removing from inside the box to be able to lift any one of the shift solenoids out once its been

unbolted.

There is NO easy way of checking any earth’s that go to these solenoids as the are all earthed

using a very short lead thats earthed / attached to a bolt inside the gear box itself.

BUT before writing the gear box off you need to be sure that the fault is what it says it is…

I say this because I had exactly the same fault happen to my gto and even though I bought a

second hand gearbox to replace my broken one it never needed fitting as my box was not at

fault…

The TCU or what you called the control unit and assume was the one you changed and was the

one thats bolted flat on the floor behind the stereo and NOT the one bolted upright as thats the

engine ECU can and does give false reading… The TCU has no way of checking itself for faults

so if it’s circuitry is faulty making it unable to control or operate any of the shift solenoids then it

will incorrectly say that the fault is the solenoid inside the gearbox and NOT itself…

Also changing the TCU over for another to try doesn’t necessarily mean that it’s not the TCU at

fault… it depends where and what kind of condition the TCU was in when you replaced it…

leaking caps inside can suddenly go down from working one minute and not the next

causing the TCU to stop working correctly… I bought a replacement TCU for mine which

worked and fixed my gearbox problem and drove the car for only 1 week… then turned the

engine off one night and the following morning the TCU was shot again.

A fishy smell coming from the TCU usually is the first signs of the caps leaking and the TCU

close to braking… I also have found that once the caps go altogether and the TCU stops working

correctly… replacing them with new doesn’t always fix the TCU and make it work again… so

must be caught before the TCU goes down altogether… check this by opening the TCU casing

and in most cases you can see if the Caps are staring to leak… if so replace them straight away.

If you know anything about car electronics and if not get an Auto Electrician as you can make

each of the solenoids operate by feeding the correct power voltage to the 4 pin plug while it’s

disconnected from the main car wiring loom… DONT just slap 12 volts directly to each of the

pins as it could damage any of them that are in good working order… I had a friend of mine who

is an Auto Electrician do mine for me… and would have to check with him what voltage he used

to test them for me… If the solenoid is working correctly then you will clearly hear it clicking

from inside the gear box which means theres no need to pull the gearbox out of the car, but look

else where for the fault… Don’t have the engine running when doing this test

Don’t waste your time going to the main dealers to buy a new SHIFT CONTROL SOLENOID A

as according to main dealers near me they have no way of telling which one is solenoid A and

will only offer you the complete set of 4 at a cost of £100’s

below are some pics I’ve done for you that may help…

NOTE… if removing the Block of 3 oil Pressure operated Solenoids there is a membrane with a

very small ball bearing and tiny spring that can easily be lost… if removing the Block of 3 oil

Pressure operated Solenoids while the gear box is still in the car there is a method in which I was

able to change mine which will keep this spring and ball bearing in place… but to long to explain

how right now unless asked.

I hope this is of help