Or if you can find someone near you who doesn’t mind you could borrow theirs. Its a very quick job. As craig said its not worth spending the money until you know that solves it as it could also be the PTU. Just to play with your head a bit I had a failed PTU which meant I wasn’t getting a spark on 2 cylinders earlier this year and the car still ran and started up very easily on 4 cylinders so I am not convinced its your problem. But definitely worth investigating.

Agreed, A 6g72 engine will run on 4 cylinders.

Albeit, very lumpy.

Not at all convinced it is why the car will not start.

Transpose the coils, see if the fault swaps over.

That could narrow it down a lot.

There is a test procedure in the manual for the PTU.

You can resistance check the HT leads., numbers in manual.

There is a resistance check for the coils, numbers in manual.

Could be coils, PTU, ECU, HT leads, wiring?

Your non starting fault does sound more fuel related though, as you have started it fires up briefly, although this could be the ECU.

I believe the ECU DR will test the ECU for free? Maybe I am wrong about this? I have never used him, a electronics mate does my things like that.

Like I said above, test each system, one at a time. Narrow it down this way, correcting as you go. This car could have many, many faults. An ebay non starter can be a knightmare for the inexperienced.

Marty

Well I thought fuel at first and I ran a 12v wire straight to the test port form battery then turned the engine and it was still cranking. Is it possible for the fuel pump to run but not be enough pressure to fire up? When I unbolted the fuel hose and cranked the fuel was going in to a bottle. I am just testing the rear bank spark plugs at the moment as the front three plugs seemed to be fine. ( I had each spark plug out at a time resting on valve cover and recorded on phone as I cranked and I was getting spark).

Only if the fuel filter is SERIOUSLY blocked.

Sounds to me more like the injectors are not opening, for whatever reason. There are many possible reasons.

Can I ask which test port you are applying 12v to?

Marty

The black one near the battery which is on same loom as the blue speed tester.

And can you hear the fuel pump running?

Bear in mind, this is just a test the fuel pump itself runs. It does not test that it actually runs when it should., it is not a system test.

There is a relay test, which will mimic the system and initiate the pump, using the wiring/relay etc.

It also doesn’t test there is sufficient pressure. There is a separate test for that. I doubt that is the fault though.

However, if it runs on this test, and it runs on the relay test, it’s not probable the fault is the fuel pump.

Is there anyone nearby who can lend you a known good ecu to slave in?

Also, does your check engine light come on?

Even if it doesn’t, there could be a code, which would help narrow this dpwn.

The ecu can be downloaded using an analogue voltmeter. Or one of the many logging systems out there.

Marty

I can hear the fuel pump running when using the test port. I left this 12v going to the pump while I cranked engine so I would imagine this would rule out the relay as well if the engine still doesn’t come in to life?

I don’t know anyone who can lend me an ECU to hand unless there is someone in Manchester with an mk1 N/A GTO. I will check the ECU codes next using the diagnostic port near fuse box using voltmeter.

Agreed, not the fuel pump or relay.

You need an analogue meter, (one with a needle). A digital one will not work in this case.

You are counting needle sweeps, and there are long and short sweeps.

You allocate 10 to each long sweep, 1 to each short one. They run in numerical order, with a pause inbetween codes, and the codes cycle, so if you miss one, it will come around again.

The procedure is in the manual, as are the codes.

You can sometimes end up ‘creating’ fault codes during diagnosis, so be aware of this.

This occurs as you disconnect things with the ignition on, that sort of thing.

Marty

i would still sort your timing out make sure the crank pulley is set on the T and the top four are lined up correctly if your exhaust valves are still slightly open on compression stroke you wont get enough compression to fire and keep firing and you will end up with the unburnt fuel hence the flooding likewise if the inlet valve isnt open when it injects it wont vaporise as it goes into the chamber and it will just run in as liquid when it finally opens

mark

Stupid me bought a digital voltmeter. At least I know that the ECU isn’t dead as its sending out signals. Its probably going to be the timing belt so I might get it to a garage and get them to look at the timing issue.

Peter

You absolutely certain the crank is pulley is lined up correctly?

Can you get pictures of the crank pulley lined up, and then a pic of the front/rear banks lined up?

If you are getting fluctuating voltages out of the ecu on a digital meter, then it almost certainly has a code for you.

An analogue voltmeter is cheap

meter

Marty

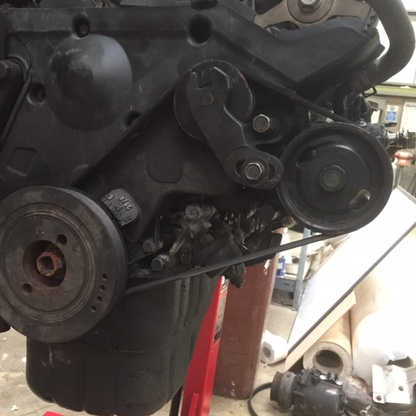

I can’t see the crank pulley for the timing belt as there is another pulley in front of it for auxiliary I think. I would need to remove that first to see the crank pulley behind it. I will check tomorrow.

Yes, you can see the timing mark with the pulley fitted.

Bear in mind this pic is from the manual for installation of the belt, and is 1 tooth out deliberately. Yours should line up.

Marty

also if your timing cover is still fitted when you look at it through the wheel arch there is a little notch in the pulley itself you can see it easier in this pic coz the engine is out of the car

mark

Hey,

I cant get to the crankshaft gear as the lower timing cover is in the way and I don’t have the tools to remove the larger pulley in front of it. I did notice however that the larger pulley does have a mark/indent on it that I would imagine has to match up to the indicator/ timing mark on the timing belt cover:

This was taken when I aligned the cams at the top to the valve cover markings. Does this pulley reflect how far out the crank pulley is?

The answer to that is…possibly.

Let me explain.

The timing mark on the pulley is mounted on the outer metal ring.

This ring is bonded to the inner part with a rubber part in between. A really common problem with these is the outer part becomes disbonded, so the outer part cn move independently from the inner. This makes the outer mark unreliable as a guaranteed way of checking the timing, unless you KNOW the pulley is good.

Also, we have had several instances of the pulleys been incorrectly fitted. There is an alignment pin, which I have seen crushed and distorted, as the pulley was fitted, making the pulley mark unreliable.

For checking of the cam timing, I would be inclined NOT to use the pulley mark as a reference, and use the toothed wheel instead.

The mark on the pulley really serves as a way to measure base timing.

As a guide, the no1 cylinder should be at TDC with it all lined up.

Also, you should be lining up the crank pulley, and checking the cams, not the other way around. Sounds academic, but it really isn’t. Keep turning the crank pulley until no1 cylinder is at TDC , with the crank lined up. (using a reliable mark)

Then you can check the cams.

I personally think you are probably barking up the wrong tree here, as you have stated the engine runs briefly, and nicely.

Still, good to be certain though

I would also do a compression test on all 6. You are looking for similar numbers from all 6. It’s more important they are all similar, than looking for actual numbers(within reason) No more than 14psi difference between cylinders. Reason for this is, you will probably use an off the shelf tester, and there is no way the gauge will be accurate. It WILL give you differences though.

Like I stated above, you can chase your tail for ages, fault diagnosing. Entirely up to you, of course, but you could spend ages guessing, spend a fortune guessing, and still not fix it.

Not trying to put you off at all, just so you are doing this ‘eyes open’, and we don’t get a thread later on stating, “these cars are s**t, and the owners club doesn’t know jack” I have seen it happen too often in situations like this.

Personally, given your inexperience with these crs, I would ship it off to Ben at Eurospec, get it fixed. Drive it, enjoy it.

They are an expensive car to learn on, and it usually doesn’t go well.

I certainly wouldn’t be asking a local garage to look at it!

Marty

Whilst I agree with Marty here that the difference between cylinder compression is more important that the figure itself I think in your case your compression test could confirm if that alignment mark is right or not. Being as far off as it is you will have mashed the valves into oblivion. Therefore little to no compression. If you have decent compression figures then it will confirm that mark is wrong. The differences between front and rear bank compression will also confirm that one of the cams is 1 tooth out of alignment as you suspect. Do a compression check and post the results. We will try and help as best we can!

Again I agree with Marty that the best bet would be to give it to Ben and let him find the fault. However, I also understand why you want to achieve the results yourself. It gives a great sense of accomplishment. So I would say take the advise given and respect it but if you choose to ignore it and carry on yourself then good on you for persisting and again we will help were possible.

When I aligned the bottom pulley to the T mark the first cam was off by two teeth and the others by three. I am not sure if like you said that is accurate.

Hi Peter,

As Marty has already said, the marks on the crank pulley can be a waste of space, there is a crank pulley that is available, don’t know which Mitsy vehicle it is from but it fits the GTO. The marks on that pulley are 90 degrees out. Totally useless for timing the engine. Get TDC first on cylinder No1. then check the timing, I use as preference, the marks on the cam covers, not the cam pulleys, the reason for this is there are so many marks on my cam pulleys that using them for a guide is hopeless. If yours doesn’t line up first time turn the engine over again trying to find TDC, using a big bar and socket on the bottom pulley, doing it this way you can also find if there is resistance in the engine, either the other cylinders compressing or, hopefully not this, something locking or grinding. If the marks are near enough on the second try you can then judge where the timing is out, if at all.

My mates N/A had this problem, couldn’t get it running for more than 10 seconds, then nothing. Sent the ECU away to the ‘Doctor’ in Plymouth, now it runs sweet as a nut.

Terry